ASTARIGLAS® provides a solution for the marine industry with ASTARIGLAS® NAUTICAL and ASTARIGLAS® NAUTICAL EXTREME. It has the best combination of properties for demanding fabrication and installation processes of various parts and maintaining its high quality in harsh environments.

ASTARIGLAS® is your perfect choice to use in various segments.

From advertising to transportation, hospital, food and beverages, and many other industries.

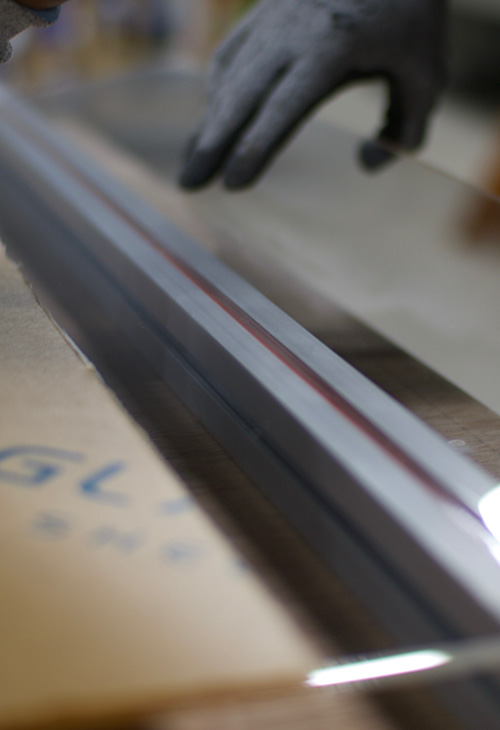

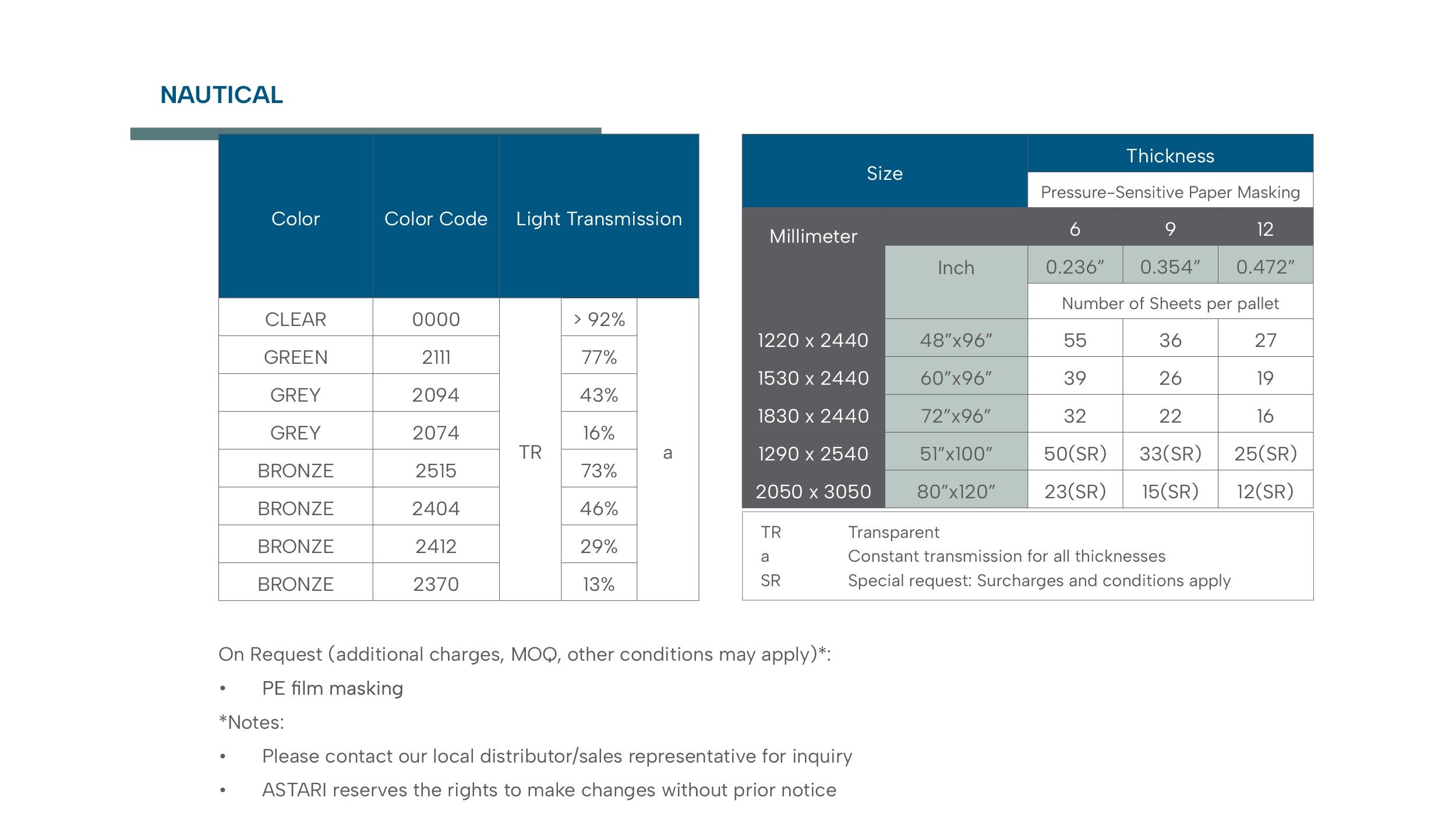

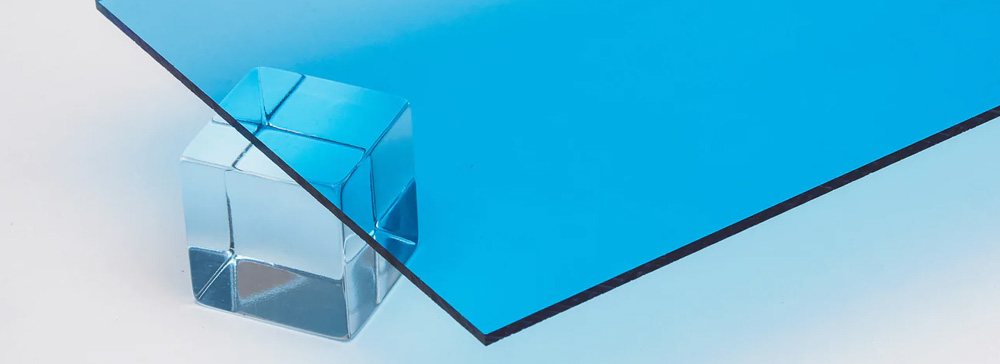

ASTARIGLAS® NAUTICAL is an enhanced formula, cross-linked and easy forming cast acrylic sheet that provides additional protection against seawater and a variety of chemicals such as cleaning agents. It provides outstanding optical quality and comes in multiple thicknesses and colors.

From 0.236" up to 0.472"

From 48" x 96" up to 80" x 120"

Paper Masking

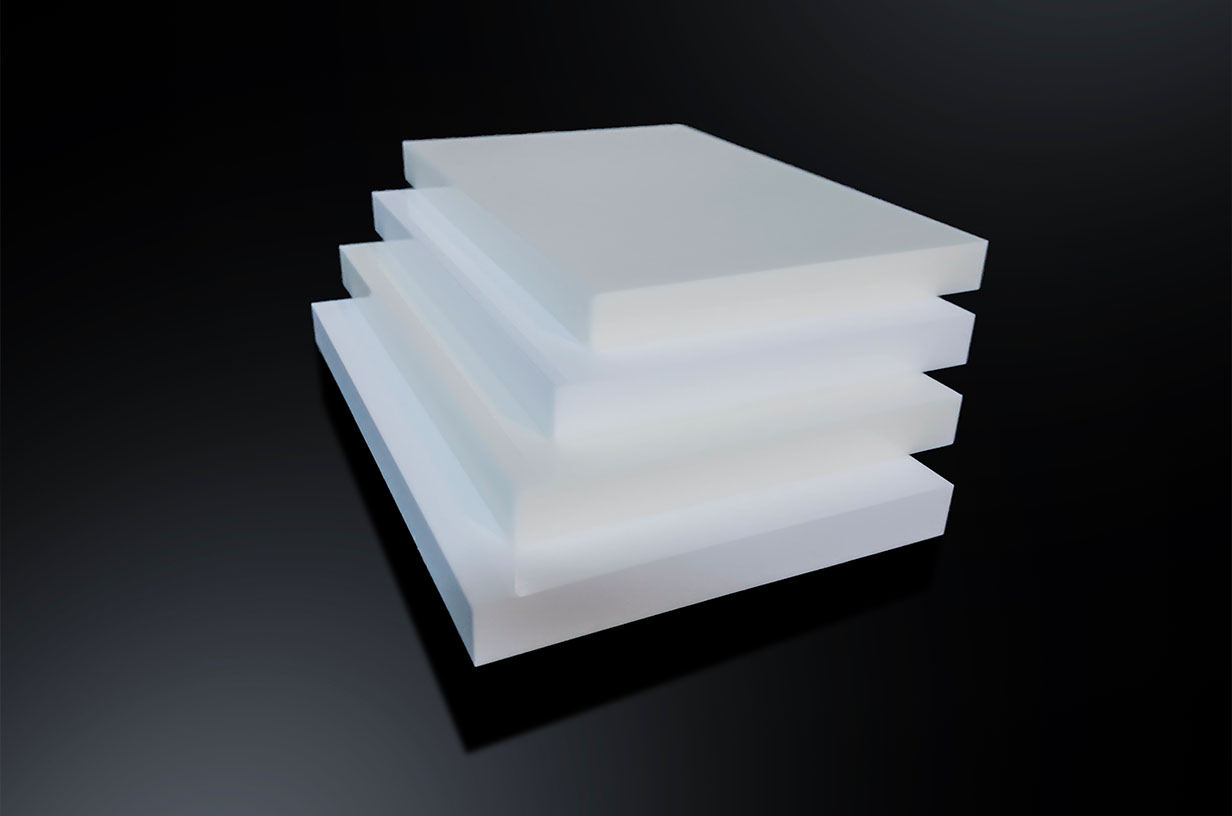

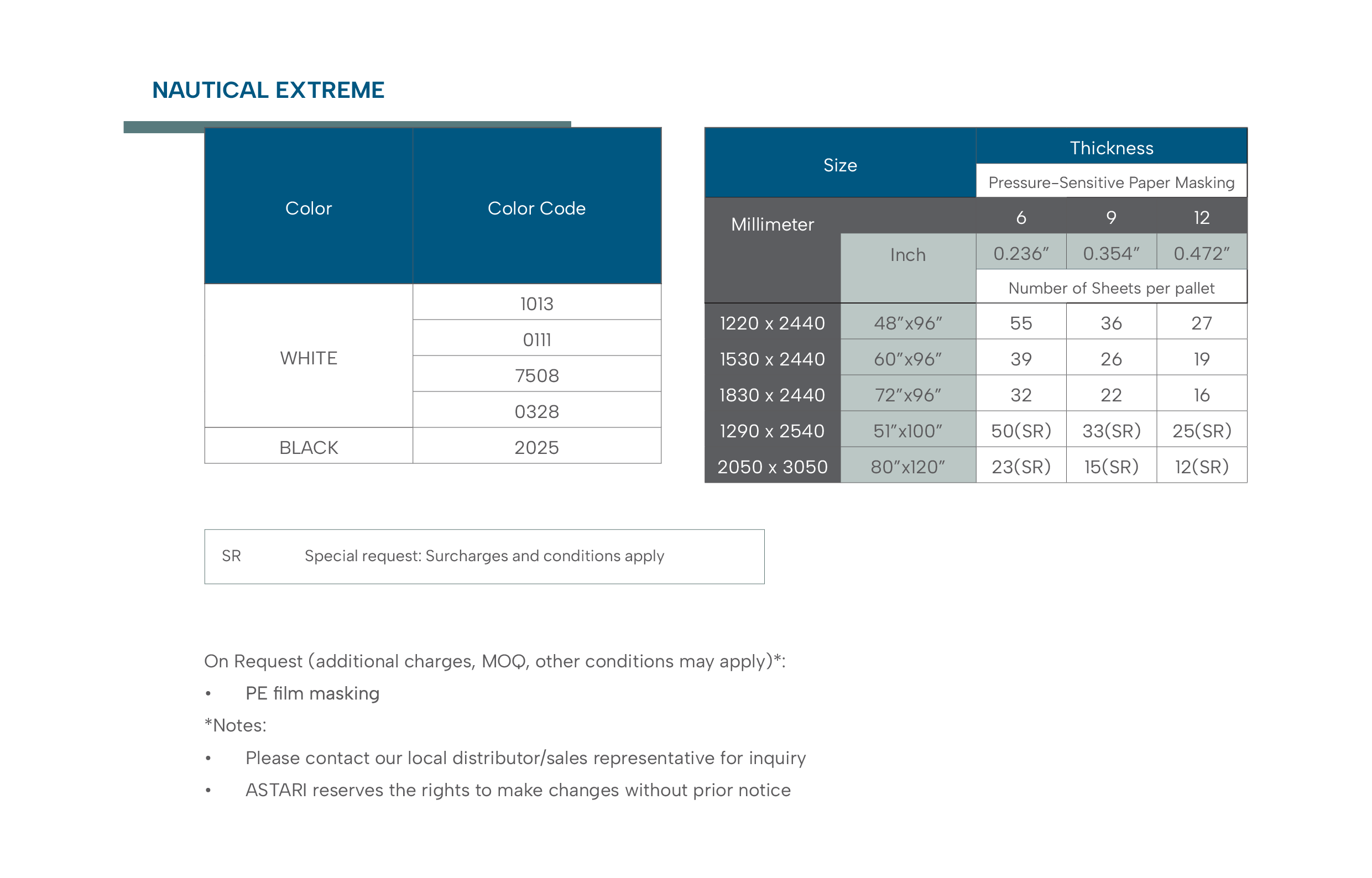

ASTARIGLAS® NAUTICAL EXTREME is an impact-modified cell cast grade. It is the best material for the marine environment providing additional impact resistance, shorter fabrication and installation time, and is cross-linked to increase chemical resistance.

From 0.236" up to 0.472"

From 48" x 96" up to 80" x 120"

Paper Masking

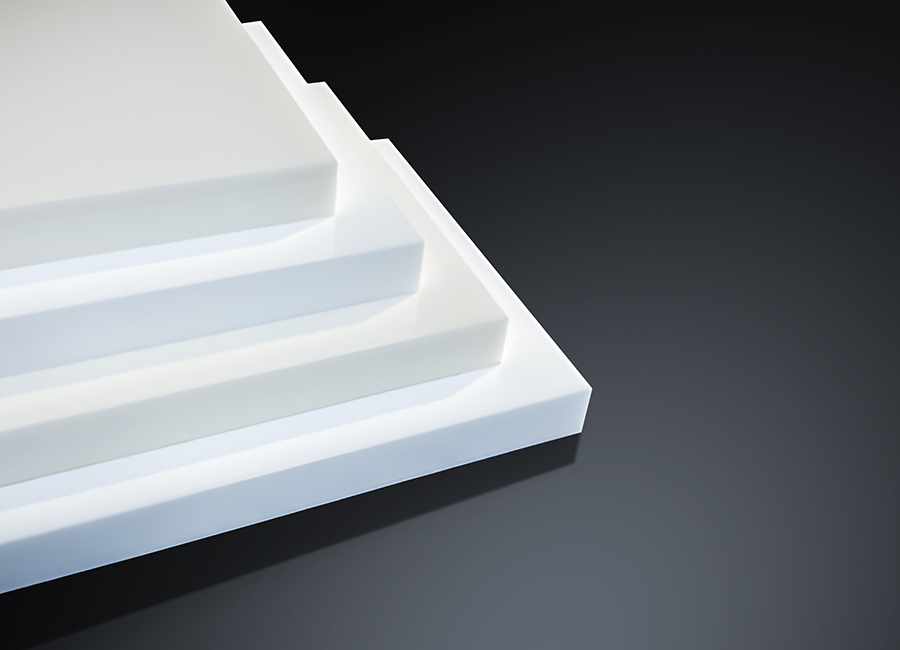

Various opals and whites with different light transmittance rates

Click below for instant access to our ASTARIGLAS® CAST ACRYLIC SHEET Handling & Storage.

Click below for instant access to our ASTARIGLAS® CAST ACRYLIC SHEET Technical Data Sheet.

Click below for instant access to our ASTARIGLAS® CAST ACRYLIC SHEET Chemical Resistance Properties.

Click below for instant access to our ASTARIGLAS® CAST ACRYLIC SHEET.

Find out more about our certification and compliance.

All ASTARIGLAS® sheet have been certified by Underwriters Laboratories to UL 94HB, the Standard for Safety of Flammability of Plastic Materials (for slow burning on a horizontal specimen).

ASTARIGLAS® BR have been certified by UL 752 level 1, this product provides protection against three shots of a 124-grain 9mm full metal copper jacket with lead core at an fps between1175 and 1293.

All ASTARIGLAS® Acrylic Sheets are manufactured to meet the standard specification of ISO 9001:2015.

All ASTARIGLAS® Clear and Opal Sheet products are in compliance with the applicable provisions of RoHS 3 Directive 2015/863/EU.

All ASTARIGLAS® Clear sheet do not contain any chemical known to the State of California to cause cancer, birth defects, or any other reproductive defects.

Please be advised that all ASTARIGLAS® clear products are in compliance with the FDA Food Additive Regulation 21 CFR177.1010 (acrylic and modified acrylic plastics, semi-rigid and rigid) for use in contact for all types of food except for high alcohol content foods (greater than 8% alcohol) at or below room temperature.

All ASTARIGLAS® sheet complies to EPA regulatory on PBT chemicals.

All ASTARIGLAS® clear sheet meets the American National Standard For Safety Glazing Motor Vehicles And Motor Vehicle Equipment Operating On Land Highways (ANSI Z26.1-1996).

All ASTARIGLAS® Clear sheet conforms to REACH regulation and do not contain any substances included in SHVC’s 244 lists in a concentration in excess the specified threshold limits.

All ASTARIGLAS® sheet complies to New York State Education Department (NYESD) flammability standards for plastic glazing used to construct sneeze guards or separators.

All ASTARIGLAS® Clear sheet meets the standard of ANSI Z26.1, a standard used by Department of Transportation (DOT).

All ASTARIGLAS® Cast Acrylic Sheets are manufactured to meet the standard specification of ASTM D 4802-10.

All ASTARIGLAS® Clear products are biocompatible and in compliance to ISO 10993-5 (Cytotoxicity).

All ASTARIGLAS® products are BPA free.

ASTARIGLAS® SW is manufactured to meet the standard specification of EN 263 Compliance.

ASTARIGLAS® is easy to fabricate.

We prepared fabrication guidelines to make your working with ASTARIGLAS® easier.